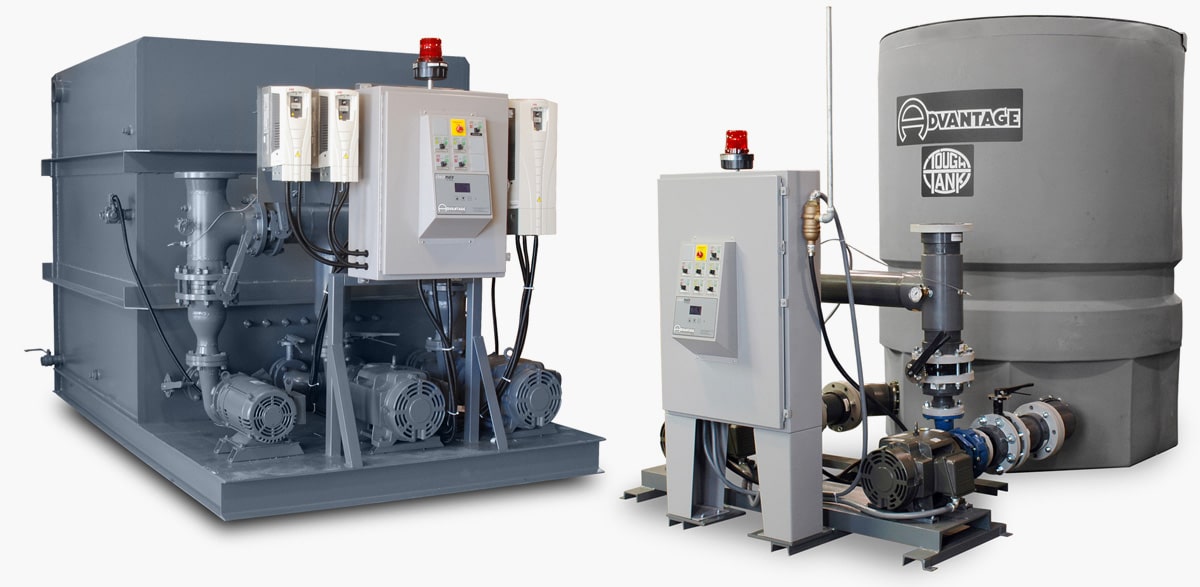

Pump Tank Stations

Integrated Water Circulation for Process Cooling

Pump tank stations serve as the heart of a process cooling system, combining water storage, pumped circulation, and flow management into one centralized platform. These systems maintain steady water pressure, support multiple cooling loads simultaneously, and balance flow across the entire plant.

Built for continuous operation, pump tank stations typically feature non-corrosive reservoirs, centrifugal process pumps, optional standby pumps, and easy-access manifolds for simple distribution. Many designs incorporate welded steel tanks, stainless steel components, and TEFC pumps for durability and long service life. Capacities range from compact, small-footprint stations to large, high-volume systems suited for multi-process facilities.

Pump tank stations ensure reliable supply water, reduce fluctuations in flow or pressure, and simplify the integration of chillers, heat exchangers, and auxiliary cooling equipment. With options such as automated tank level control, digital monitoring, temperature readouts, and alarm diagnostics, these stations support efficient plant operation with minimal oversight.

Process Water Distribution: Delivers consistent flow to injection molding, extrusion, molding machines, and other load points through well-organized manifolds.

Heat Load Balancing: Helps maintain stable temperatures by supporting recirculation between cooling equipment and process circuits.

System Integration: Works seamlessly with central chillers, cooling towers, and filtration modules to create a complete cooling solution.

Operational Flexibility: Stations can manage multiple zones, accommodate system expansion, and provide reliable backup pumping capacity.

Maintenance Efficiency: Easy-access tank openings, pump isolation valves, and clear routing simplify routine service and system checks.

Peak Demand Support: Helps maintain pressure stability during high-load events or seasonal cooling increases.