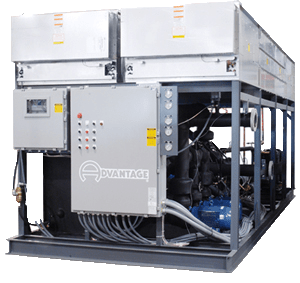

Outdoor Chillers for Food & Beverage

Advantage Weatherproof Low-Temperature Systems

In food and beverage facilities with limited indoor space, Advantage outdoor chillers deliver centralized, high-capacity cooling from rooftop or ground-level pads. These NEMA 4X-rated units withstand rain, snow, wind, and temperatures from -20°F to 125°F while supplying glycol or water to multiple process lines.

Advantage outdoor chillers feature galvanized steel cabinets, epoxy-coated condenser coils, stainless steel pumps, brazed plate evaporators, and Copeland scroll compressors with crankcase heaters and low-ambient kits. Available from 20 to 540+ tons in air-cooled or water-cooled configurations, they include insulated piping penetrations, remote monitoring, and sanitary tri-clamp outlets. Variable speed fans and hot gas bypass ensure stable operation in all seasons.

Advantage outdoor systems provide critical cooling for large-scale brewing, dairy, bakery, and bottling plants while freeing valuable production floor space. Built with UL 1995 outdoor listing and NSF-rated components, they meet HACCP, FSMA, and USDA standards. Integrated pump tanks, filtration, and predictive diagnostics support 24/7 reliability in harsh environments.

Outdoor Cooling Solutions

Maximizing plant efficiency and space requires durable cooling systems built for external installation. Advantage Engineering leads in outdoor chillers with a full range of rugged, high-performance units engineered for food and beverage operations.

Brewery Plant Cooling:

Outdoor central chillers supply 25°F glycol to 50+ jacketed fermenters and bright tanks.

Dairy Silo Cooling:

Rooftop units maintain 34°F milk storage with redundant pump stations.

Winery Barrel Room:

Ground-mounted chillers deliver 28°F glycol for temperature-controlled barrel aging.

Bakery Freezer Supplement:

Outdoor systems boost capacity for blast chilling and frozen dough production.

Remote Processing:

Weatherproof chillers serve off-site cold storage or satellite plants.

Space Optimization:

Eliminates indoor mechanical rooms, allowing expansion of production lines.