Advantage Chillers for Packaging & Processing

Heat from filling, sealing, and labeling can cause container deformation, poor label adhesion, or weak seals. Advantage portable and central chillers supply 33–40°F water or glycol to molds, rollers, and cooling tunnels, ensuring dimensional stability, crisp graphics, and hermetic packaging.

Applications

- Beverage Bottle Cooling: Chillers cool PET and glass bottles post-hot-fill to 85°F in under 60 seconds, preventing collapse and enabling immediate labeling.

- Dairy Cup & Pouch Sealing: Systems maintain 35°F mold temperatures for yogurt and cheese packaging, ensuring clean cuts and leak-proof seals.

- Shrink Sleeve & Label Tunnels: Glycol chillers cool mandrels and rollers to 40°F, preventing label distortion and improving adhesion on high-speed lines.

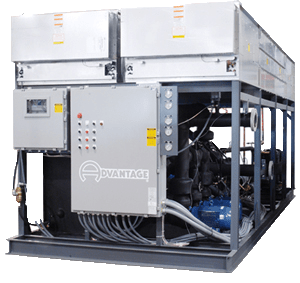

Portable Chillers

Mobile Spot Cooling Units

- 1–40 Ton Capacity Range

- Casters & Quick-Connect Hoses

- ±1°F Setpoint Control

Central Chillers with Cooling Tunnels

High-Volume Line Integration

- 50–500+ Ton Scalability

- Stainless Steel Distribution Manifolds

- PLC Line Speed Synchronization

The Benefits of Advantage Chillers for Packaging & Processing

In high-speed packaging, even minor temperature fluctuations can cause downtime and waste. A national beverage co-packer experienced 12% label rejection due to bottle ovality after hot-filling. After deploying two Advantage 30-ton portable chillers with inline cooling tunnels, they reduced bottle temperature from 190°F to 85°F in 45 seconds, eliminated deformation, and increased line speed by 18%.

Advantage packaging chillers feature non-ferrous circuits, tri-clamp fittings, and washdown-rated controls to withstand daily sanitation. Variable speed pumps and dynamic setpoints adjust flow to match filler output, while remote HMI integration allows operators to monitor temperatures from the control room. These systems not only prevent defects but reduce energy costs by up to 25% through part-load efficiency.

From craft breweries to multinational dairy plants, Advantage delivers the precision, mobility, and hygiene required to keep packaging lines running at peak performance.