Advantage Chillers for Laser Cutter Machine Cooling

High-power laser cutting generates intense localized heat in the resonator, optics, and power electronics. Thermal drift causes beam misalignment, lens fouling, reduced cut speed, and premature component failure. Advantage closed-loop chillers deliver 50–68°F (±0.1°F) deionized water or glycol to critical zones using microchannel heat exchangers, redundant filtration, and ultra-pure fluid circuits—preventing downtime and maintaining ISO 15616 cut quality across stainless, aluminum, and titanium.

Applications

- Fiber Laser Resonators: Chillers stabilize 1070 nm seed lasers at 25°C, preventing wavelength drift and ensuring 0.1 mm kerf consistency in 30 kW systems cutting 1" steel at 400 IPM.

- CO2 Laser Optics: Dual-circuit systems cool beam delivery mirrors and focusing lenses to 18°C, eliminating thermal lensing and maintaining 50 µm focus stability over 8-hour shifts.

- Power Supply & Chiller Integration: Rack-mounted chillers remove 15 kW from IGBT modules and capacitors, preventing thermal runaway and extending MTBF beyond 100,000 hours.

- Multi-Head Systems: Central plants with flow balancing manifolds serve 6+ laser heads from a single 200-ton chiller, reducing footprint and enabling synchronized nesting.

- Assist Gas Pre-Cooling: Optional glycol loops chill nitrogen to -10°C, improving edge quality and reducing dross in high-pressure oxygen-free cutting.

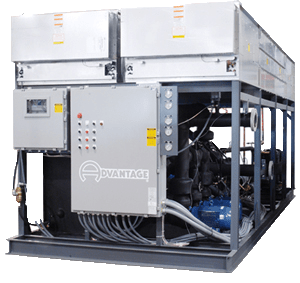

OACS Central Chillers

Outdoor Air-Cooled Systems

- 10–500+ Ton Capacity

- Scroll or Screw Compressors

- Weatherproof NEMA 4X Controls

MG Series Portable Chillers

Packaged Air-Cooled Units

- 2–40 Ton Range

- Non-Ferrous Plumbing

- Digital Scroll

The Benefits of Advantage Chillers for Laser Cutter Machine Cooling

In precision laser fabrication, thermal management defines performance and profitability. A contract manufacturer running six 20 kW fiber lasers experienced 22% downtime from optics fouling and beam drift due to inconsistent chiller performance. After deploying an Advantage 180-ton central plant with microchannel heat exchangers and predictive flow control, they achieved ±0.08°F stability, reduced lens cleaning from daily to monthly, increased cut speed by 28%, and added $1.8M in annual throughput.

Advantage laser chillers feature 316L stainless microchannel evaporators, 0.5 µm DI filtration with conductivity monitoring, and non-ferrous pumps to prevent particulate contamination. PLCs with Profinet and OPC-UA integrate directly with Trumpf, Amada, and Bystronic controllers, enabling real-time beam quality feedback and automated thermal compensation. Redundant circuits and auto-changeover ensure zero interruptions—even during peak summer loads.

From single-head job shops to automated lights-out factories with 50+ lasers, Advantage delivers the precision, reliability, and connectivity required to push laser cutting performance to its limits—day in, day out.