Advantage Chillers for Poultry Pre-Cooling

After evisceration, poultry carcasses must be chilled to 40°F within 4–8 hours per USDA regulations. Advantage central water chillers supply consistent 32–34°F water to screw, drag, or air-agitation chillers, minimizing bacterial growth (Salmonella, Campylobacter) while preserving meat quality and moisture retention.

Applications

- Immersion Screw Chillers: Chillers maintain 32°F water in continuous-flow tanks, cooling 15,000+ birds/hour with counterflow efficiency.

- Air-Chill Systems: Glycol units supply 28°F air via evaporators, reducing cross-contamination risk in dry processing environments.

- Post-Chill Drip & Storage: Systems hold 34°F in drip lines and blast cells, preventing temperature rebound before packaging.

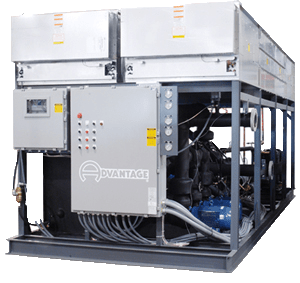

Water-Cooled Central Chillers

High-Capacity Immersion Systems

- 100–1,000+ Ton Scalability

- Redundant Compressors & Pumps

- Automated Chlorine & pH Control

Glycol Air-Chill Units

Dry Processing Cooling

- 28–32°F Air Delivery

- Stainless Evaporator Coils

- Washdown NEMA 4X Design

The Benefits of Advantage Chillers for Poultry Pre-Cooling

In poultry processing, rapid and uniform chilling is critical to food safety and yield. A large integrator faced USDA non-compliance due to inconsistent screw chiller temperatures. After installing an Advantage 600-ton water-cooled central chiller with automated water management, they achieved ±0.5°F stability, reduced chilling time by 22%, and improved moisture retention by 1.2%—adding millions in annual value.

Advantage poultry chillers feature 316L stainless circuits, CIP-ready tri-clamp manifolds, and integrated water treatment (chlorine injection, pH monitoring) to maintain hygiene and prevent biofilm. PLC controls with SCADA integration log temperatures in real time for FSIS reporting, while predictive diagnostics prevent downtime during peak kill schedules. These systems not only ensure compliance but reduce water usage by up to 40% via recirculation and heat recovery.

From 50,000-bird/day plants to fully integrated complexes, Advantage delivers the capacity, sanitation, and reliability demanded by modern poultry pre-cooling.