Advantage Chillers for Fermentation Cooling

During fermentation, exothermic reactions generate heat that can alter flavor, stall yeast, or promote off-flavors if not controlled. Advantage glycol chillers maintain tight jacketed vessel temperatures (±0.5°F) to optimize microbial activity, ensure complete attenuation, and deliver consistent batches.

Applications

- Brewery Fermentation: Glycol chillers regulate wort from 48–72°F in conical fermenters, enabling precise ale and lager profiles while preventing diacetyl and fusel alcohols.

- Winery Temperature Control: Chillers maintain 55–65°F during red wine fermentation and 45–55°F for whites, preserving aromatics and preventing stuck ferments.

- Cultured Dairy & Kombucha: Systems hold 86–110°F for yogurt and kefir incubation, then crash to 39°F to halt fermentation and extend shelf life.

Glycol Chillers

Glycol Chillers

- ±0.5°F Temperature Stability

- Tri-Clamp Sanitary Connections

- Automated Cold Crash Profiles

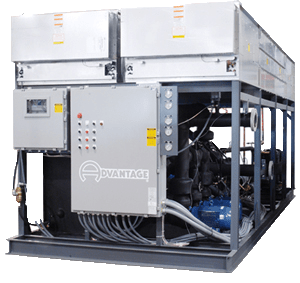

Outdoor Central Chillers

Weatherproof Glycol Systems

- NEMA 4X Epoxy-Coated Coils

- Low-Ambient Operation to -20°F

- Redundant Pump Stations

The Benefits of Advantage Chillers for Fermentation Cooling

In fermentation-driven food and beverage production, temperature control is the difference between award-winning flavor and batch failure. A craft brewery once struggled with inconsistent diacetyl levels and stalled ferments due to poor jacket cooling. After installing an Advantage central glycol chiller with zoned control, they achieved ±0.5°F stability across 20 fermenters, reduced cold crash time by 40%, and eliminated off-flavors.

Advantage fermentation chillers use food-grade propylene glycol, non-ferrous circuits, and sanitary tri-clamp manifolds to prevent contamination. Hot gas bypass and electronic expansion valves maintain evaporator pressure during low-load incubation, while automated ramp/soak profiles sync with brewery software. These systems not only protect product integrity but also reduce energy costs by up to 30% versus oversized fixed-speed units.

From small-batch kombucha to 500-barrel lager production, Advantage chillers deliver the precision, hygiene, and reliability needed to scale fermentation with confidence.