Advantage Chillers for Chemical & Pharmaceutical Processes

Exothermic reactions, solvent distillation, and crystallization generate heat that can degrade APIs, shift yields, or create safety hazards. Advantage process chillers maintain tight tolerances (±0.1°F) using non-reactive fluids, stainless steel circuits, and hazardous-area-rated components to protect product integrity and operator safety.

Applications

- Reactor Jackets: Glycol or brine chillers control batch temperatures from -40°F to 250°F during synthesis, preventing runaway reactions and ensuring consistent polymorph formation.

- Solvent Recovery: Low-temp condensers recover VOCs and high-value solvents at -20°F, reducing waste and emissions in distillation columns.

- Crystallization & Lyophilization: Chillers supply -80°F brine to freeze-dryers and cooling baths, enabling precise crystal size control and stable drying cycles.

Glycol Chillers

Glycol Chillers

- ±0.5°F Temperature Stability

- Tri-Clamp Sanitary Connections

- Automated Cold Crash Profiles

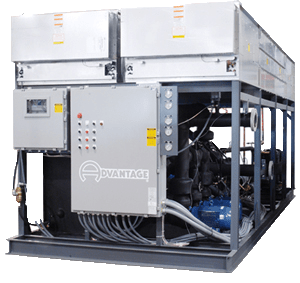

Outdoor Central Chillers

Weatherproof Glycol Systems

- NEMA 4X Epoxy-Coated Coils

- Low-Ambient Operation to -20°F

- Redundant Pump Stations

The Benefits of Advantage Chillers for Chemical & Pharmaceutical Applications

In high-value API production, temperature deviations can cost millions in lost batches. A specialty chemical manufacturer experienced polymorph instability due to reactor hot spots. After deploying an Advantage -40°F brine chiller with jacketed flow control, they achieved ±0.1°F uniformity, increased yield by 8%, and passed FDA process validation on first submission.

Advantage chemical/pharma chillers feature 316L electropolished circuits, FDA-approved heat transfer fluids, and full documentation packages (IQ/OQ/PQ). PLCs with 21 CFR Part 11-compliant data logging integrate with DCS systems, while redundant compressors and auto-changeover ensure zero downtime during critical campaigns. These systems not only safeguard reactions but reduce solvent loss by up to 60% through precise condensation.

From pilot-scale R&D to 10,000L commercial reactors, Advantage delivers the precision, safety, and compliance required for modern chemical and pharmaceutical manufacturing.