Advantage Chillers for Tooling & Die Cooling

Heat buildup in molds and dies from aluminum or zinc causes dimensional inconsistency, surface defects, and premature tool failure. Advantage high-turbulence chillers supply 40–70°F water or oil at 30–120 GPM with ±0.5°F stability through conformal cooling channels, baffles, and bubblers—optimizing heat extraction, minimizing stress, and enabling faster cycles in automotive, aerospace, and consumer goods tooling.

Applications

- High-Pressure Die Casting: Chillers cool H13 steel dies to 350–450°F between shots, preventing solder defects and extending die life from 80,000 to 120,000+ cycles in aluminum and magnesium casting.

- Injection Molding: Multi-zone systems maintain 50–60°F in P20 and 420SS molds, reducing warpage in thick-walled PC/ABS parts and cutting cycle time by 25% in 800-ton presses.

- Progressive Stamping: Oil chillers keep 60°F hydraulic fluid in 1,000-ton presses, preventing viscosity drop, seal leaks, and thermal expansion during high-speed steel forming.

- Hot Forging Dies: Water-based systems cool D2 and H11 dies to 200°F post-forge, reducing thermal fatigue cracks and enabling 50% faster production of titanium aerospace fittings.

- Conformal Cooling Channels: High-velocity chillers support 3D-printed copper inserts and lattice structures, achieving 40% faster heat removal than traditional drilled channels.

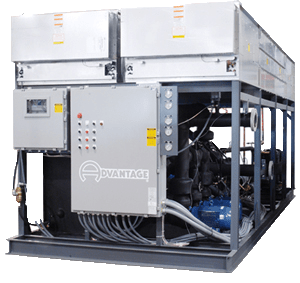

OACS Central Chillers

Outdoor Air-Cooled Systems

- 10–500+ Ton Capacity

- Scroll or Screw Compressors

- Weatherproof NEMA 4X Controls

MG Series Portable Chillers

Packaged Air-Cooled Units

- 2–40 Ton Range

- Non-Ferrous Plumbing

- Digital Scroll

The Benefits of Advantage Chillers for Tooling & Die Cooling

In high-cavitation tooling, thermal uniformity determines part quality and tool longevity. A medical device molder struggled with 15% scrap from sink marks and warpage in 128-cavity syringe barrel molds. After implementing an Advantage 200-ton central chiller with turbulent flow manifolds and conformal channel monitoring, they achieved ±0.4°F across all cavities, reduced cycle time from 28 to 19 seconds, cut scrap below 1%, and extended mold life by 60%.

Advantage tooling chillers feature stainless steel brazed-plate evaporators, variable-speed pumps with 0.1 GPM resolution, and non-ferrous quick-connect circuits to prevent corrosion and contamination. PLCs with Mold-Masters and Synventive hot runner integration enable automatic temperature ramping during startup and shutdown, while predictive thermal modeling prevents hot spots before they form. Optional oil heating circuits support hybrid water/oil tools in a single system.

From prototype shops running one-off dies to Tier 1 suppliers with 500+ active molds, Advantage delivers the flow, precision, and durability needed to maximize tool performance and minimize downtime—cycle after cycle, year after year.