Advantage Chillers for Metal Plating, Finishing & Anodizing

Electroplating, anodizing, and chemical finishing processes generate significant heat from current flow, chemical reactions, and rinse water evaporation. Uncontrolled bath temperatures cause coating defects, poor adhesion, hydrogen embrittlement, and accelerated chemical breakdown. Advantage titanium and PVDF heat exchanger chillers maintain 70–95°F (±0.5°F) in acid, alkaline, and cyanide baths, using non-ferrous fluid circuits, sealed electrical enclosures, and corrosion-proof coatings to withstand aggressive environments for decades of reliable service.

Applications

- Hard Chrome Plating: Chillers remove 50–200 kW of heat per tank, maintaining 120–140°F in chromic acid baths to prevent burning, pitting, and uneven deposition on hydraulic rods and industrial rolls.

- Electroless Nickel (EN): Systems hold 185–195°F with ±1°F stability in phosphorus baths, ensuring uniform 0.001" coatings on aerospace and oilfield components while extending bath life by 30%.

- Type II & III Anodizing: Titanium evaporators cool sulfuric acid to 32–70°F, controlling oxide layer thickness, color consistency, and dye uptake in architectural and defense aluminum parts.

- Zinc & Cadmium Plating: Closed-loop chillers prevent cyanide bath overheating above 85°F, reducing toxic gas evolution and ensuring bright, ductile finishes on fasteners and automotive hardware.

- Rinse Water Recovery: Multi-stage systems chill post-plating rinse tanks to 60°F, minimizing drag-out losses and enabling closed-loop water recycling with zero discharge.

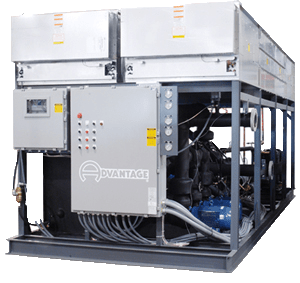

OACS Central Chillers

Outdoor Air-Cooled Systems

- 10–500+ Ton Capacity

- Scroll or Screw Compressors

- Weatherproof NEMA 4X Controls

MG Series Portable Chillers

Packaged Air-Cooled Units

- 2–40 Ton Range

- Non-Ferrous Plumbing

- Digital Scroll

The Benefits of Advantage Chillers for Metal Plating, Finishing & Anodizing

In high-value metal finishing, bath temperature control is non-negotiable for quality, safety, and compliance. A leading aerospace plater faced 18% rework due to dull, uneven hard chrome deposits caused by bath temperatures exceeding 135°F. After installing an Advantage 80-ton titanium immersion chiller with real-time ORP feedback, they achieved ±0.4°F stability, reduced rework to under 1%, extended bath life by 42%, and passed NADCAP audit with zero findings.

Advantage plating chillers are engineered with Grade 2 titanium or PVDF heat exchangers, non-metallic pumps, and NEMA 4X fiberglass enclosures to resist acid vapors, cyanide fumes, and caustic mists. PLC controls with 4–20mA interfaces integrate with rectifiers and dosing systems, while built-in conductivity and pH monitoring enable predictive chemical replenishment. Optional heat recovery preheats rinse water, cutting energy costs by up to 40% and supporting sustainability goals.

From small job shops running decorative nickel to Tier 1 suppliers plating landing gear, Advantage delivers the durability, precision, and chemical compatibility required to produce flawless finishes—batch after batch, year after year.